Glass Bottle Cap Compatibility: A Guide to Choosing the Right Closure

In the world of glass packaging, selecting the right bottle is only half the challenge. The other critical component is choosing the appropriate closure—or cap—that ensures your product remains safe, fresh, and user-friendly. Glass bottle cap compatibility is not just about aesthetics or function; it directly impacts sealing integrity, shelf life, tamper evidence, consumer experience, and regulatory compliance.

Whether you’re packaging beverages, cosmetics, pharmaceuticals, or food, understanding how to select the correct cap is crucial.

Why Closure Compatibility Matters

Closure compatibility refers to the functional and dimensional fit between the cap and the bottle neck. A mismatch can result in:

- Leaks or spills, reducing shelf appeal and causing product loss

- Contamination, affecting product safety and shelf life

- Consumer frustration, damaging brand loyalty

- Regulatory non-compliance, especially for food, pharmaceutical, and hazardous products

A properly matched cap and bottle not only create an effective seal but also enhance user interaction, preserve product integrity, and support your branding strategy.

Understanding Neck Finishes and Thread Sizes

Before choosing a closure, it’s important to understand the neck finish of your glass bottle. This includes the diameter, thread configuration, and height of the neck—key metrics for determining cap compatibility.

Measuring Neck Size:

Neck sizes are usually specified using two measurements:

- Outer diameter of the neck (in millimeters)

- GPI thread finish, which defines the thread style and height

For example, a neck finish of “28-400” means:

- 28 mm outer diameter

- 400 GPI thread style (one continuous thread turn)

Common Neck Finish Standards:

- GPI (Glass Packaging Institute): North American standard

- DIN (Deutsches Institut für Normung): European metric standard

- SP (Specialty): Custom finishes for niche applications

Matching closures must align precisely with the bottle’s neck size and thread configuration. A 28-400 cap fits only bottles with a 28-400 neck.

Types of Closures for Glass Bottles

Closures come in many forms depending on product type, use, and industry standards. Below are the most common categories:

Screw Caps

- Use: Beverages, oils, personal care, pharmaceuticals

- Material: Metal or plastic

- Sealing Method: Threads on both bottle and cap create a tight seal

- Advantages: Reusable, tamper-evident options available

Cork and T-Corks

- Use: Wine, spirits, perfumes, specialty foods

- Material: Natural cork, synthetic cork, wood, or plastic tops

- Sealing Method: Friction fit within the neck

- Advantages: Premium look, ideal for anaerobic storage

Crown Caps

- Use: Carbonated beverages, beer

- Material: Steel with plastic liner

- Sealing Method: Crimped onto the bottle neck

- Advantages: Airtight for carbonation, tamper-resistant

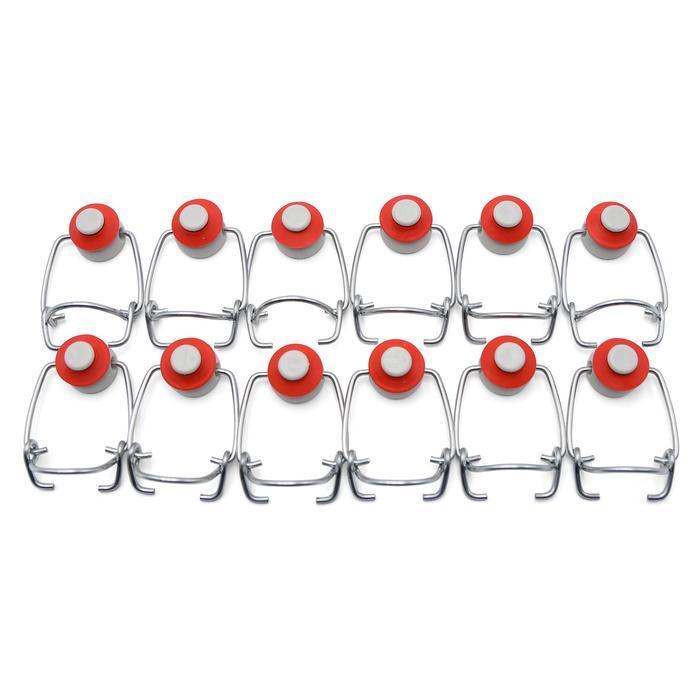

Flip-Top / Swing-Top Caps

- Use: Craft beverages, fermented products

- Material: Ceramic, metal wire, rubber gasket

- Sealing Method: Mechanical pressure holds the cap in place

- Advantages: Reusable, eco-friendly, vintage appeal

Droppers, Sprayers, and Pumps

- Use: Pharmaceuticals, cosmetics, aromatherapy

- Material: Plastic or metal

- Sealing Method: Screw or snap fit with dip tube

- Advantages: Controlled dispensing, hygienic design

Tamper-Evident Closures

- Use: Pharmaceuticals, food and drink

- Material: Plastic or metal with breakaway bands

- Sealing Method: Breaks or deforms when first opened

- Advantages: Ensures product integrity, regulatory compliance

Closure Materials: Pros and Cons

Closure materials vary in cost, function, appearance, and recyclability—each offering distinct advantages and limitations depending on product needs.

| Material | Typical Use | Pros | Cons |

| Aluminum | Beverages, cosmetics | Lightweight, recyclable, premium look | Can dent easily |

| Tinplate | Food, wine, oil | Cost-effective, corrosion-resistant | Prone to rust if scratched |

| Polypropylene (PP) | Pharma, cosmetics, food | Durable, resistant to chemicals | Not biodegradable |

| High-Density Polyethylene (HDPE) | Industrial, pharma | Tough, resistant to impact | Less aesthetic appeal |

| Silicone/Rubber | Dropper caps, swing-tops | Flexible seal | Not always recyclable |

| Natural Cork | Wine, spirits | Breathable, biodegradable | Variable quality, prone to mold |

| Synthetic Cork | Spirits, perfumes | Consistent, long shelf life | Less traditional look |

Closure Liners & Seals

Plastisol (PVC) Liners

- Metal twist-off & lug caps, ideal for hot-fill glass applications

- Forms a hermetic seal upon heating, indicated by a “pop” on opening.

Pressure-Sensitive Liners (PS-22)

- Adhesive bonds forming under torque; suitable for glass bottle lips

- One-time use, not ideal for oils or liquids long-term.

Polyseal Cone Liners

- LDPE conical inserts that conform to the bottle neck inside

- Excellent for volatile, acidic products—common in pharma and essential oils.

Linerless (Land Seal)

- Integrated plastic flange compresses against bottle lip

- Cost-effective and simpler; ensure the finish is clean and precise.

Induction Liners

- Multilayer liners (foil, wax, pulp, polymer) heat-sealed to bottle by induction

- Creates tamper-evident, airtight seals for high-value liquids.

Matching Closures to Bottle Finishes

Thread Finishes

- CT (Continuous Thread): Full helix—used with screw caps.

- Lug (e.g., 33–400): Quarter-turn closures.

- Standards: GPI finish numbers define sizing and threading

| Neck Finish (GPI Code) | Neck Diameter (mm) | Thread Type | Common Cap Types | Typical Applications |

| 18-400 | 18 | Single thread | Screw caps, dropper caps, pump/sprayer | Essential oils, serums, pharmaceuticals |

| 20-410 | 20 | Continuous thread | Screw caps, flip-top caps, disc caps | Personal care, cosmetics |

| 24-410 | 24 | Continuous thread | Screw caps, dispensing pumps, fine mist | Lotions, toners, skincare products |

| 28-400 | 28 | Single thread | Screw caps, child-resistant caps | Household chemicals, food jars |

| 33-400 | 33 | Continuous thread | Screw caps, tamper-evident caps | Edible oils, syrups, condiments |

| 38-400 | 38 | Wide thread | Screw caps, foam liners, induction seals | Juices, sauces, vitamins |

| 43-400 | 43 | Continuous thread | Lug caps, screw caps | Jams, pickles, condiments |

| 48-400 | 48 | Continuous thread | Lug caps, vacuum seals | Glass jars, canned goods |

| Crown (26 mm) | 26 | Non-threaded crimp type | Crown caps (metal crimped) | Beer, soft drinks, sparkling water |

| Cork Finish (Tapered) | Varies | Friction fit | Corks, T-corks | Wine, spirits, artisanal beverages |

| Swing-Top (Ceramic) | Varies | Hinged clamp | Flip-top/swing-top caps | Kombucha, beer, reusable beverage bottles |

| DIN18 (Euro Dropper) | 18 | Threaded with dropper fit | Dropper inserts, child-resistant caps | Aromatherapy, tinctures |

Sealing Surface

Needs to be flat, clean, and free of imperfections—critical for linerless and pressure-sensitive systems.

Material Compatibility

Glass vs. cap material (metal, plastic) interactions must avoid corrosion or leaching. E.g., use cone liners for highly acidic products.

Product-Specific Closure Considerations

Each product category has its own requirements for bottle and cap compatibility.

Food & Beverage

- Must meet food safety standards like FDA and EU regulations

- Consider oxygen barrier properties and carbonation pressure

- Tamper-evident features are often required

Pharmaceuticals

- Child-resistant caps may be mandated

- Tamper-evidence and dosage control are critical

- Liners must be chemically inert

Cosmetics & Skincare

- Aesthetic appeal is essential

- Pump or sprayer compatibility

- UV protection for sensitive formulas

Household & Industrial Chemicals

- Caps must prevent leaks and accidental exposure

- Resistant to solvents, acids, or oxidizers

- Often require child-proof designs

Environmentally Responsible Closure Choices

Eco-conscious brands are shifting toward more sustainable, eco-friendly packaging solutions. Closure materials can impact recyclability and environmental footprint.

Trends in Sustainable Closures:

- Mono-material caps that match the bottle for recycling ease

- Biodegradable corks and stoppers made from sugarcane or plant-based polymers

- Flip-top closures designed for repeated use in refillable packaging

- Reducing material usage to minimize weight and lower carbon emissions.

When choosing closures, consider not just product protection, but also end-of-life impact.

Troubleshooting Common Issues

Leaky Caps:

Misaligned threads, warped necks, insufficient torque.

Solution: Adjust torque, use compressible liners, confirm finish dimensions.

Difficult Opening:

Over-tightening or rigid liners.

Solution: Use slip agents, choose lighter torque caps, add knurling.

Seal Failure (Foil Liners):

Poor induction settings, debris.

Solution: Clean, calibrate induction, validate liner type.

Corrosion:

Acidic contents + reactive liners.

Solution: Use inert liners like cone, PTFE, or induction.

Regulatory Non-compliance:

Missing tamper bands, incorrect threading.

Solution: Audit closure features, verify finish code standards.

How to Source the Right Cap

When selecting a glass bottle and cap system, work with suppliers who offer:

- Neck finish specifications

- Cap liner compatibility

- Tamper-evidence features

- Testing certifications (FDA, ISO, etc.)

- Customization capabilities

Request samples and run real-world tests before scaling up production.

Cap Type vs Application Matrix

| Cap Type | Common Bottle Types | Best For | Sealing Strength |

| Screw Cap (Plastic) | Dropper bottles, oils | Food, pharma, skincare | Moderate |

| Screw Cap (Metal) | Spirits, sauces, aromatherapy | Premium food & drink | High |

| Cork | Wine, perfume, spirits | Oxygen-sensitive products | Moderate |

| Crown Cap | Beer, soda | Carbonated beverages | Very High |

| Flip-Top | Kombucha, craft drinks | Reusable, artisan beverages | High |

| Pump/Sprayer | Lotions, cleaning solutions | Controlled dispensing | Moderate |

Choosing the right closure for your glass bottle is a critical decision that affects functionality, appearance, and customer satisfaction. More than a cap—it reflects quality, safety, branding. To choose wisely:

- Understand your product’s specific needs.

- Understand your bottle’s neck finish

- Choose materials and liners wisely

- Test rigorously for compatibility

- Align with sustainability and branding goals

Whether you opt for a standard screw cap or a custom swing-top closure, investing time in cap compatibility can make all the difference in the marketplace.