Guide to Swing Top Bottles 2025: A Complete Manufacturer’s Handbook

In an age where sustainability, aesthetics, and function merge, swing top bottles have become a staple across multiple industries—beverages, home brewing, cosmetics, and even household storage. As a manufacturer specializing in premium glass packaging, we understand the evolving demands of both businesses and consumers.

This comprehensive 2025 guide to swing top bottles covers everything from design, materials, applications, customization, and regulations to help you choose the right solution for your product.

What Are Swing Top Bottles?

Swing top bottles, also known as flip-top, lightning, or bail bottles, feature a reusable mechanical closure system. The cap is attached to the bottle by a metal wire loop and is sealed with a rubber gasket, ensuring an airtight, leakproof seal. Swing tops provide both visual appeal and practical sealing advantages.

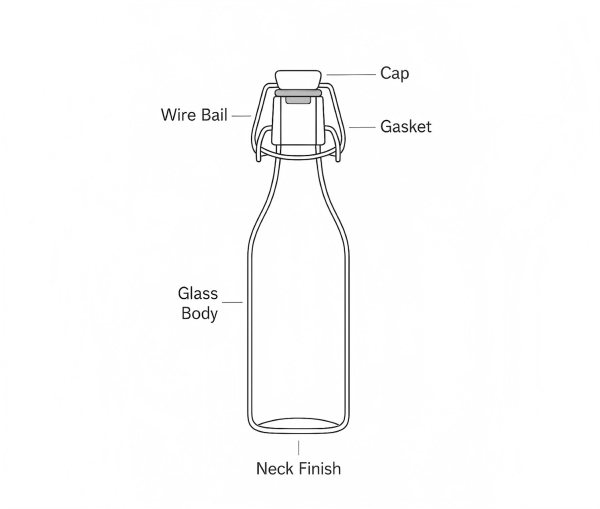

Anatomy of a Swing Top Bottle

Understanding the components of a swing top bottle helps businesses customize or source better solutions:

Glass Body: Available in clear, amber, green, or frosted finishes. Can be embossed, silk-screened, or labeled.

Neck Finish: Specially designed to accommodate wire closures.

Swing Top Closure System:

- Cap: Made of plastic, ceramic, or stainless steel.

- Gasket: Typically made from rubber or silicone.

- Wire Bail: Stainless or galvanized steel for durability.

The integrated system ensures secure resealing and adds to product longevity.

Applications Across Industries

Swing top bottles are highly versatile and suitable for a range of industries in 2025:

Beverages

- Craft beer & kombucha: Airtight seal preserves carbonation.

- Cold brew coffee & fresh juices: Reusable solution for health-conscious brands.

- Water bottles: Trendy for gourmet and premium waters.

Food Products

- Vinegars, oils, sauces: Provide a vintage look while preventing spoilage.

- Syrups & infusions: Suitable for retail, restaurants, and home use.

Cosmetics & Wellness

- Bath oils, essential oils, toners: Controlled dispensing and elegant design.

Household & DIY Storage

- Detergents, cleaners, plant-based formulas: Sustainable and refill-friendly.

- Craft storage (glitters, paints): Secure and aesthetic solution.

Home Brewing

- Small-batch brewing: Reusability and pressurization make it ideal for fermentation enthusiasts.

Advantages of Swing Top Bottles

| Feature | Benefit |

| Reusable | Environmentally friendly, cost-effective for end users |

| Airtight Seal | Preserves freshness and carbonation |

| Easy Resealing | Perfect for multi-use applications |

| Tamper-Evident Option | Ideal for commercial packaging |

| Premium Look | Enhances product image and brand recognition |

| Chemical Resistance | Compatible with many liquid types. |

| Compatibility | Available in various capacities from 100 ml to 1 liter+ |

Swing top bottles cater to modern consumer preferences—convenience, reusability, and style.

Material & Design Options in 2025

With advancements in materials and finishes, swing top bottles are no longer just standard clear glass. Manufacturers now offer:

Glass Options

- Clear Glass: Most common, versatile for labeling and visibility.

- Amber Glass: UV-resistant, ideal for light-sensitive products.

- Green Glass: Preferred in craft beer and artisanal beverages.

- Frosted Glass: Aesthetically elegant, often used in cosmetics.

Closure Materials

- Plastic Caps: Lightweight and affordable.

- Ceramic Tops: Premium, reusable for high-end beverages.

- Stainless Steel Caps: Durable, industrial-grade, long shelf life.

Gasket Colors

- Standard: White, red, orange

- Custom: Blue, green, black—for brand distinction

Bottle Shapes

- Long-Necked: Ideal for beer and kombucha

- Round-Shouldered: Suits sauces and syrups

- Square & Vintage Styles: For decorative or upscale applications

Customization Options for Brand Identity

Branding on swing top bottles goes far beyond just a label. As a manufacturer, we offer:

- Embossing or Debossing: Logos, patterns, or texts molded into the glass

- Silk Screen Printing: Permanent, heat-set branding without labels

- Hot Foil Stamping: Metallic accents for a luxurious look

- Color Spraying: Gradient or full-body bottle coloring

- Custom Closures: Gasket and cap color matching for brand themes

Customized swing top bottles become instantly recognizable and help brands command higher perceived value.

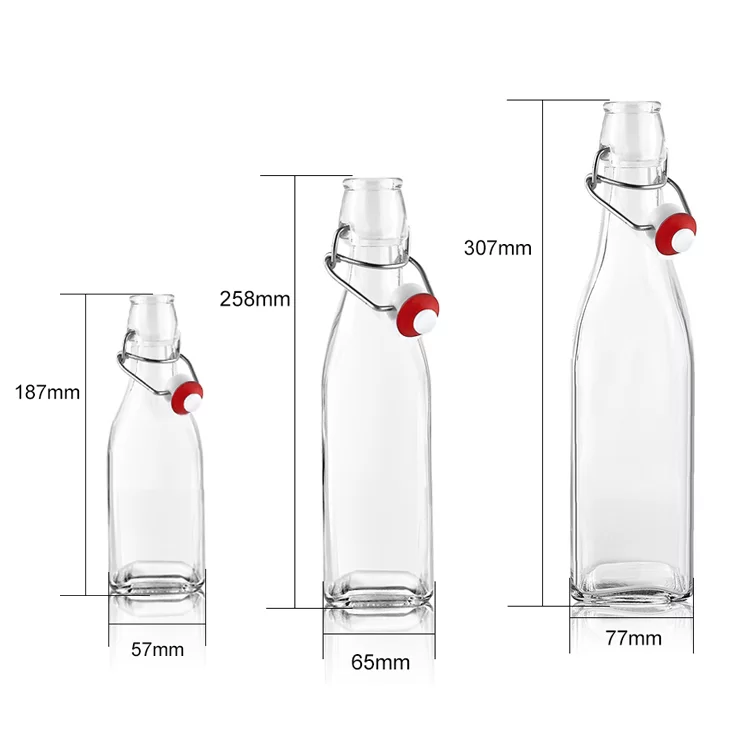

Sizing and Volume Options

Swing top bottles come in a variety of sizes to meet diverse industry needs:

| Size | Common Use Cases |

| 100 ml | Tonics, extracts, travel-size cosmetics |

| 250 ml | Juices, sauces, oils, vinegars |

| 330 ml | Kombucha, beer, cold brew |

| 500 ml | Larger beverage servings, household uses |

| 750 ml | Specialty wines, syrups, infusions |

| 1 liter+ | Family-sized drinks, storage applications |

Each bottle size provides unique advantages for portion control, shelf impact, branding, and shipping efficiency.

Manufacturing & Quality Standards

As a swing top bottle manufacturer, our quality control processes are strict and internationally compliant. Our facilities follow:

- ISO 9001 certified quality management system

- FDA Food Contact Compliance

- EU 1935/2004 Safety Standards

- SGS/BV Testing for chemical leaching and mechanical performance

Each batch undergoes:

- Dimensional consistency testing

- Impact resistance testing

- Closure integrity assessment

- Thermal shock resistance for carbonated contents

We also provide third-party certification upon request.

Sustainability and Environmental Considerations

In 2025, swing top bottles support eco-conscious trends as sustainability increasingly influences consumer purchasing decisions.

- Reusable Packaging: Reduces reliance on single-use plastics.

- Fully Recyclable Materials: Glass, rubber, stainless steel

- Zero Waste Retail Compatibility: Favored in refill stations and bulk shops

- Carbon Emission Reduction: Light-weighting technologies and optimized logistics

Brands that package with swing top bottles benefit from improved ESG (Environmental, Social, Governance) ratings and customer loyalty.

How to Choose the Right Swing Top Bottle for Your Product

Use this quick checklist to choose the ideal swing top bottle configuration for your product:

| Factor | Recommendation |

| Product Sensitivity | Use amber glass for UV protection |

| Carbonation Level | Choose ceramic or stainless cap with reinforced gasket |

| Aesthetic Appeal | Consider frosted glass or custom-painted finishes |

| Capacity Needs | Match portion size to typical consumer usage |

| Refill-Friendly Design | Opt for wider neck finishes |

| Budget Constraints | Use plastic tops with PE gasket for cost-efficiency |

Swing Top Bottle Trends in 2025

Several emerging trends in packaging are reshaping the usage and appeal of swing top bottles today.

- Smart Closures: RFID/NFC-enabled caps for digital branding and traceability

- Minimalist Labeling: Transparent labels or direct printing for a clean look

- Refill Campaigns: Incentives for returning and refilling bottles

- Heritage Branding: Vintage styles in modern markets

- Zero-Plastic Packaging: Full glass and metal constructions replacing synthetic components

These trends are shaping new demand patterns in markets like wellness drinks, plant-based products, and independent breweries.

Logistics and Shipping Considerations

Swing top bottles require careful packing to protect the closure mechanism during transit:

- Partitioned Boxes: Prevent metal parts from breaking glass

- Foam or Cardboard Inserts: Cushion bottles and absorb shock

- Cap Locking: Some closures include transport locks to prevent opening during shipping

We offer export-grade packaging services that comply with ISPM-15, UN specification boxes (for hazardous goods), and container loading optimization.

Private Label & OEM Services

As a manufacturer, we support brands with private label and OEM services including:

- Design prototyping

- Mold development

- Label printing and application

- Drop shipping

- Low minimum order quantities (MOQs) for startups

We partner with global beverage startups, skincare brands, and lifestyle product companies seeking reliable and scalable packaging options.

FAQs

Q1: Are swing top bottles safe for storing carbonated drinks?

A: Yes, with the right gasket and closure material, they handle carbonated beverages effectively.

Q2: Are swing top closures dishwasher safe?

A: Most are, but we recommend removing and hand-washing ceramic tops to preserve gasket integrity.

Q3: Can I get custom shapes and embossing?

A: Absolutely. We offer custom molds and branding options for volume orders.

Q4: Do swing top bottles support tamper-evident features?

A: Yes, we can integrate tamper-evident seals or shrink bands.

Q5: Are they suitable for hot filling?

A: Only certain glass thicknesses and closures are rated for hot-fill. Contact us for specifications.

Swing top bottles blend vintage charm with modern function in 2025. Their functional design, resealability, and premium presentation elevate both product and brand. As global consumers move toward sustainability and personalization, swing top packaging stands out as a smart, stylish, and responsible choice.

At our manufacturing facility, we empower businesses of all sizes with customizable, compliant, and high-performance swing top bottle solutions. Whether introducing a new product or updating your packaging, we’re ready to provide dependable, high-quality solutions.